Introduction to laser technology

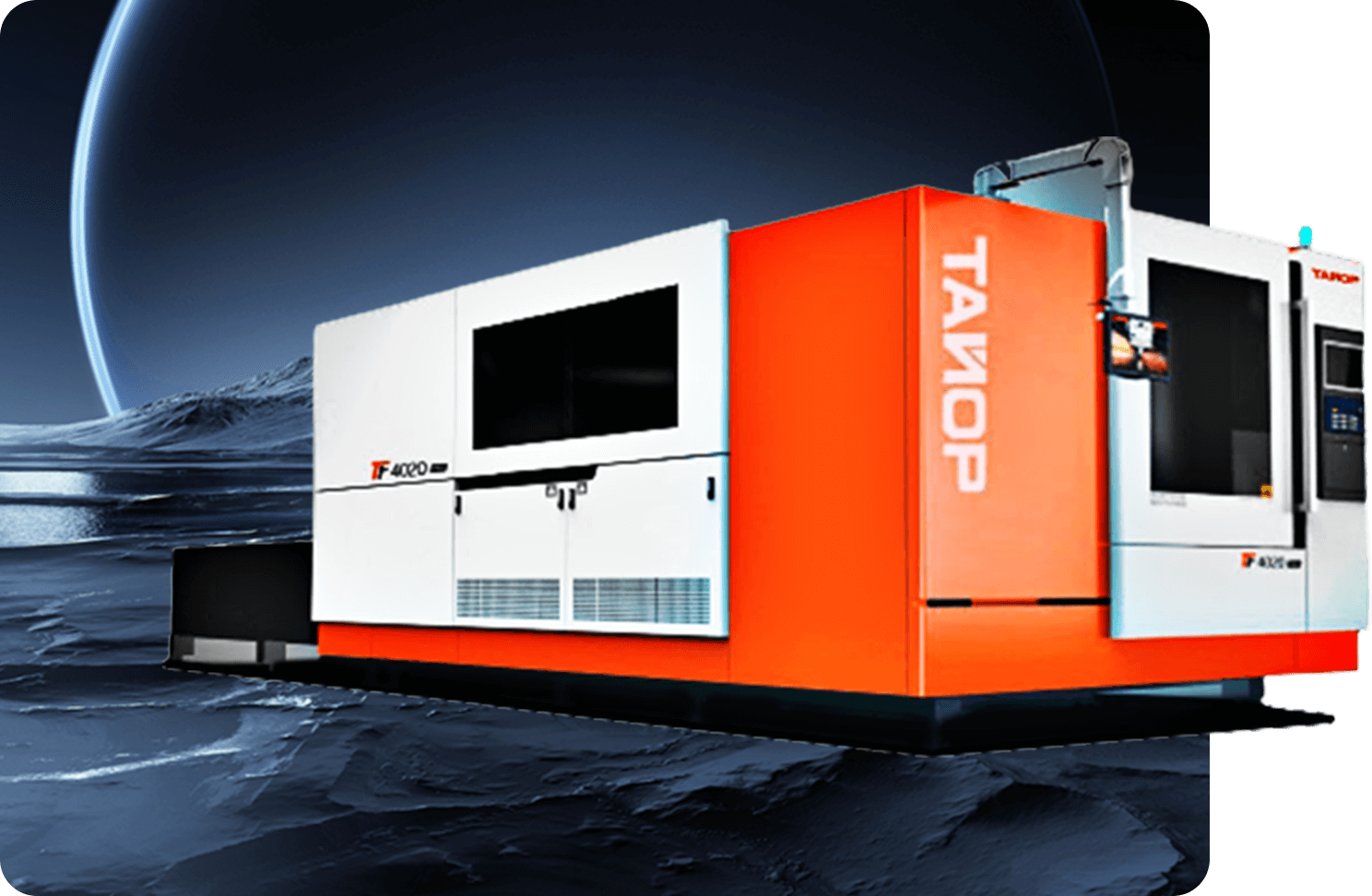

The company "Tyor Industrial Technologies" proposes innovative laser technology that promises to revolutionize industrial production due to accuracy, speed and efficiency. The main advantage of laser cutting is that it can handle the most difficult technical tasks, maintain high performance and ensure stable results. For example, laser machines that cut metal from TIOR provide maximum accuracy, even the most stringent requirements.

Modern lasers - Key advantages

Modern technology introducing TIOR products is provided to its equipment with innovative standards. Their laser machines used to cut metals, such as pipes, are specially designed to ensure continuous production. One of these achievements is the best tailor-made laser tube cutting machine. The machine is equipped with the latest fiber lasers, such as providing autofocus and power up to 60 kW.

##Main functions:

1. **High Precision Cutting: **Use powerful fiber lasers to allow you to cut parts accurately at the most stringent levels. This solution is ideal for heavy industry and decorative structures.

2. **University: **This machine is designed to use various forms of pipes, including circles, squares and even complex geometric shapes. This makes it an indispensable industrial tool.

3. **Auto Loading System: **Innovative mechanisms that provide materials improve productivity, allowing us to simplify the preparation process.

These advantages can not only be confirmed by technical features, but also by authentic comments to customers, which makes Tyor Laser Cutter ideal for many users.

Management and Energy Efficiency

In the modern production market, it is important not only to ensure high performance, but also to reduce operating costs. The laser device "TIRA" is implemented in a way that is optimally spent without the loss used for production tasks. For example, models with 1.5x3 m working area are ideal for small workshops, while 2x6 M machines meet the requirements of large factories.

For operators, the operator is provided with an interface for configuring the functions of the equipment. This not only allows for training employees in the shortest time, but also provides effective work without permanent maintenance.

Using of equipment

Laser technology is widely used in a variety of industries:

- **Automotive Industry: **High-quality laser cutting parts provide waste accuracy and minimization. This is an economically favorable solution for automakers.

- **Air Industry: **For aviation parts, the level of processing accuracy provided by laser devices is crucial.

- **Furniture Production: **Because it is possible to deal with various forms of metal pipes, TIOR equipment is an indispensable tool for designers and manufacturers.

In addition, among architects and artists, laser cutting is increasingly used in creating individual projects and in large-scale production.

Advantages of local production

One of the main reasons why enterprises choose the machine "Tira" is localized production. The conference in the Moscow region allows you to quickly provide spare parts and consumables to customers, which is particularly important for Russian companies. Therefore, the company occupies a leading position in the industry.

Conclusion

Laser machines for cutting metals can not only promote complex processing of materials, but also reduce time costs. The product "extends typical" combines engineering accuracy, high capacity and accessibility in the Russian market. Regardless of production scale, these tools can meet the widest range of demand.

To learn more about the product and technical features of powerful machines, including laser systems and pipes, you can always apply for advice by contacting a designated contact or visiting [Tayor-russia.ru] (Tayor-russia.ru). Discover new production possibilities with Tior!