Laser cutting: incredible accuracy for modern industry

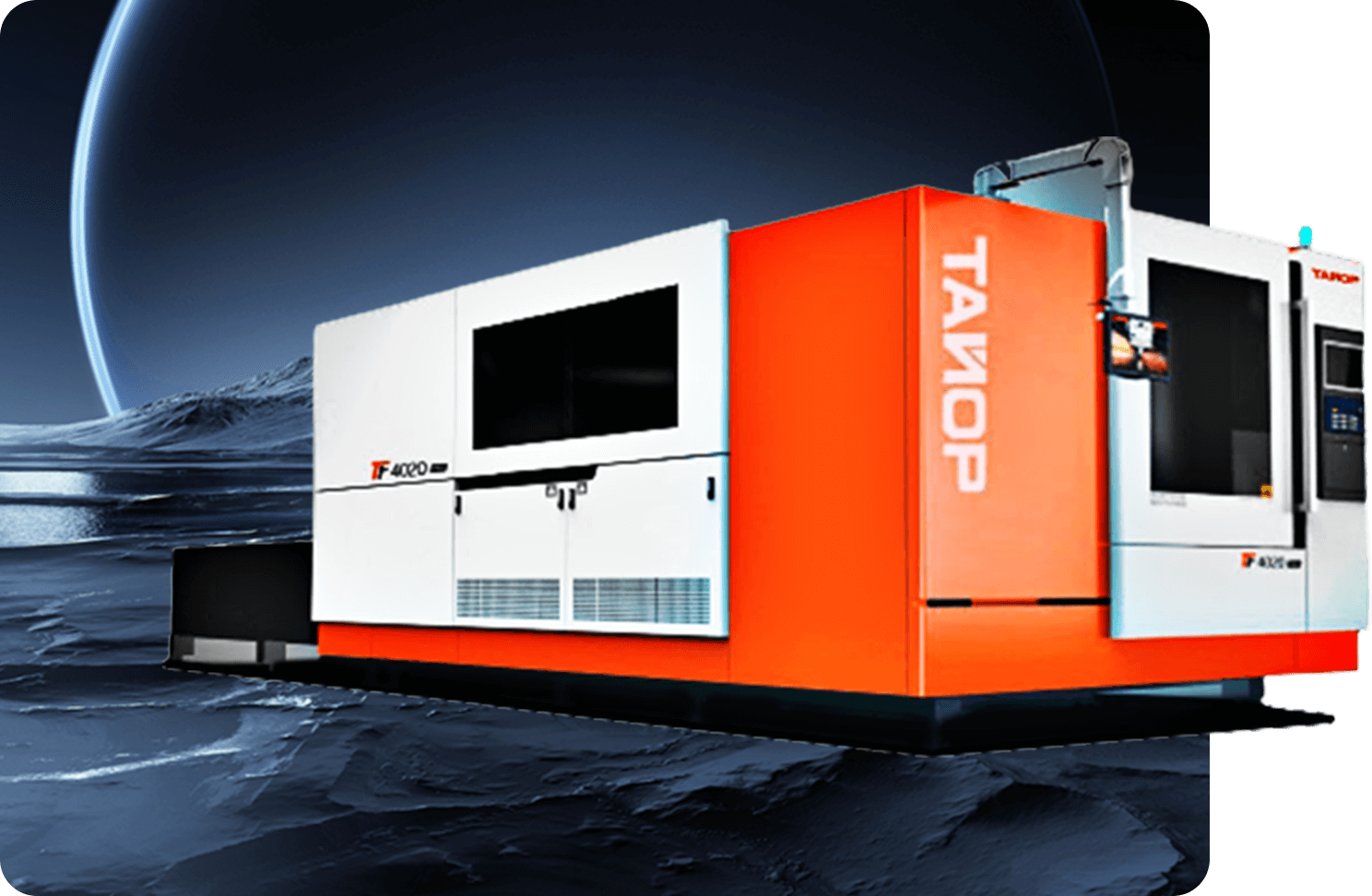

Laser cutting has become a key element of the production process in a wide variety of industries. From construction to interior design, from the auto industry to the aerospace industry - laser equipment provides high accuracy and efficiency in creating complex parts. Laser cuts for metal are especially popular, which allows you to perfectly process steel, aluminum and other metal surfaces. In this context, I would like to note an innovative product from Tyor Industrial Technologies - Tayorlaser Tube Processing Machine. This high -tech machine is adapted for processing pipes and profiles, offering a combination of accuracy, speed and versatility.

The main features of the Tayorlaser laser machines

Tayorlaser laser cutting systems are highly performance and strength, which makes them indispensable for modern factories. Here are a few key characteristics that highlight these products among competitors:

1. ** Powerful accuracy **: Tayorlaser Tube Processing Machine is famous for its ability to cut complex pipes and profiles with jewelry accuracy. Work with materials such as stainless steel, carbon steel and aluminum is supported.

2. ** Automatic processes **: the machine is equipped with an automatic supply, alignment and cutting system, which significantly reduces the need for manual tuning. This minimizes downtime and increase overall performance.

3. ** Multifunctionality **: The equipment is suitable for both standard round or square pipes and non -standard Profiles. This makes Tayorlaser indispensable for various industries, including furniture production, automobile industry and aerospace engineering.

4. ** Simple control **: A convenient interface makes the machine accessible in circuit even for users with little work experience. An independent control panel allows you to configure the parameters quickly and accurately.

The use of laser technologies in Russian -made wheels

The TIOR company is actively introducing laser solutions into Russian industry. According to the latest data, up to 67% of Russian enterprises replaced European equipment with Chinese, but more and more often selected localized solutions, such as TIORT machines made in Shanghai and collected in the suburbs.

"TIRA" offers a wide range of machine tools, including cutting for pipes with a diameter of up to 350 mm and metal cutting machines with working areas of 1.5x3 m and 2x6 m. Other configurations include compressors, stabilizers and coolers, which add to the versatility of the device. Laser wearing and cleaning are also available, which opens up new horizons for factories and factories striving to improve the quality of their products.

The Future of Fiber Lasers

Today, the company's "GV" fiber lasers have become an advanced solution in the market. They not only allow optimizing the energy efficiency of the device, but also provide remote diagnostics and configuration capabilities. This approach minimizes downtime and improves long-term performance of the machine. TIOR also implements a wide range of training programs for clients, thus providing training programs that are capable of using innovative technologies.

In addition, Tayorlaser has high environmental stability. The use of fiber lasers greatly reduces the amount of waste and reduces energy consumption. This is an important step to maintaining our environmental standards and reducing the impact of the industry on the environment. Tayorlaser machines are ideal for mass production, in which case the combination of accuracy, efficiency and environmental friendliness is important.

Why choose Tayorlaser?

Tayorlaser Tube Processing Machine and other laser cutters of the TIOR company - this is equipment that helps to modernize production processes and adapt to the new calls of the industry.

Whether it is construction, automatic industry, furniture production or interior design, with Tayorlaser you get advanced equipment that provides high performance at minimal costs.